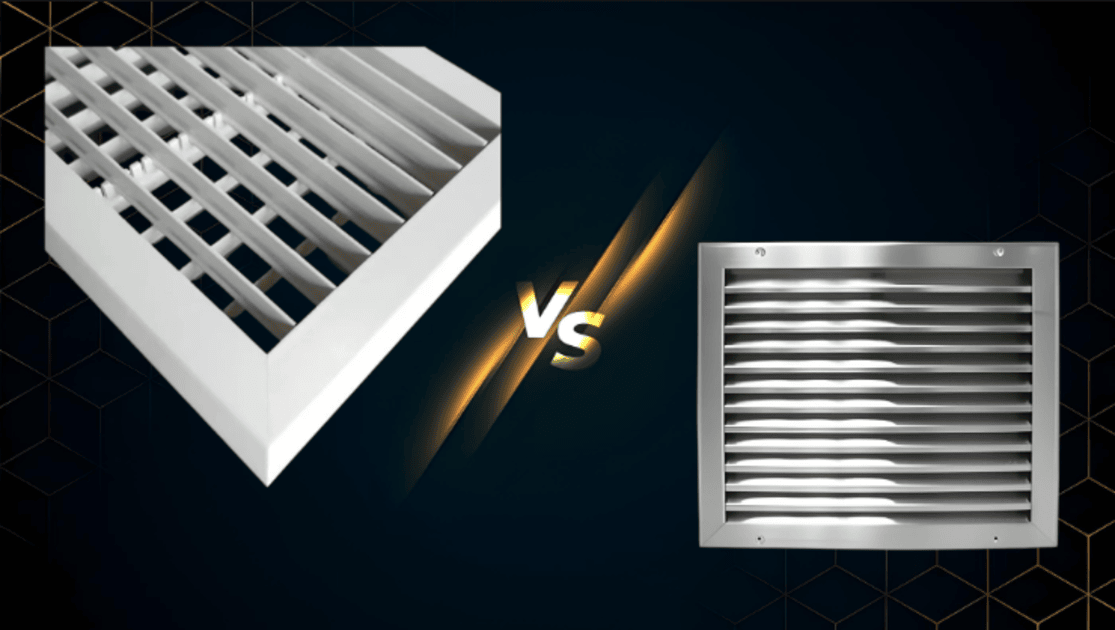

Plastic AC Grills vs Aluminium AC Grills

When it comes to selecting the right air conditioning grills for HVAC systems, contractors and MEP consultants often find themselves weighing the benefits of plastic versus aluminum options. Each material has its own set of advantages and disadvantages, making the choice dependent on specific project requirements, budget constraints, and aesthetic considerations.

Overview of AC Grills

AC grills are essential components of HVAC systems, responsible for directing airflow into and out of spaces. They are typically installed at the openings of ductwork and can be found on walls, ceilings, or floors. The primary functions of these grills include:

- Airflow Management: Directing conditioned air into a room and facilitating the return of stale air.

- Debris Protection: Preventing dust, debris, and pests from entering the ductwork.

- Aesthetic Appeal: Concealing duct openings while complementing interior design.

Plastic AC Grills

Advantages

- Cost-Effective: Plastic grills are generally less expensive than their aluminum counterparts, making them a budget-friendly option for large installations.

- Lightweight: Their lightweight nature makes them easier to handle and install, which can reduce labor costs.

- Corrosion Resistance: Plastic does not corrode, making it suitable for environments with high humidity or exposure to moisture.

- Variety of Designs: Available in various colors and styles, plastic grills can be easily matched to different interior decors.

Disadvantages

- Durability: Plastic grills can be less durable than aluminum, especially in high-traffic areas where they may be subject to impact or wear.

- Temperature Sensitivity: Extreme temperatures can cause plastic to warp or become brittle over time, potentially affecting performance.

- Limited Load Capacity: They may not support as much weight as aluminum grills, which can be a consideration in certain applications.

Aluminum AC Grills

Advantages

- Durability: Aluminum grills are robust and resistant to wear and tear, making them ideal for high-traffic or industrial environments.

- Temperature Resistance: They can withstand extreme temperatures without warping, ensuring long-term performance.

- Aesthetic Options: Aluminum grills can be painted or finished to match various design schemes, providing versatility in appearance.

- Higher Load Capacity: Suitable for applications requiring more structural integrity, such as in commercial buildings.

Disadvantages

- Cost: Aluminum grills are typically more expensive than plastic options, which can impact budget considerations.

- Weight: Heavier than plastic, which may increase installation complexity and labor costs.

- Corrosion: While aluminum is generally resistant to corrosion, it can still corrode in certain environments, particularly if not properly coated.

Conclusion

Choosing between plastic and aluminum AC grills ultimately depends on the specific needs of the project. For budget-conscious installations or environments with high humidity, plastic grills may be the better choice. Conversely, for applications requiring durability and resistance to extreme conditions, aluminum grills are likely the more suitable option.HVAC contractors and MEP consultants should assess factors such as installation location, expected wear and tear, aesthetic requirements, and budget constraints when making their decision. By understanding the strengths and weaknesses of each material, professionals can ensure optimal performance and longevity of their HVAC systems.