What are some common materials used for HVAC grills?

In the HVAC industry, selecting the right materials for grills is crucial for ensuring efficiency, durability, and aesthetic appeal. HVAC contractors and MEP consultants should be well-versed in the various materials available for HVAC grills, as each comes with its own set of advantages and disadvantages. Here’s an overview of the most common materials used in HVAC grills.

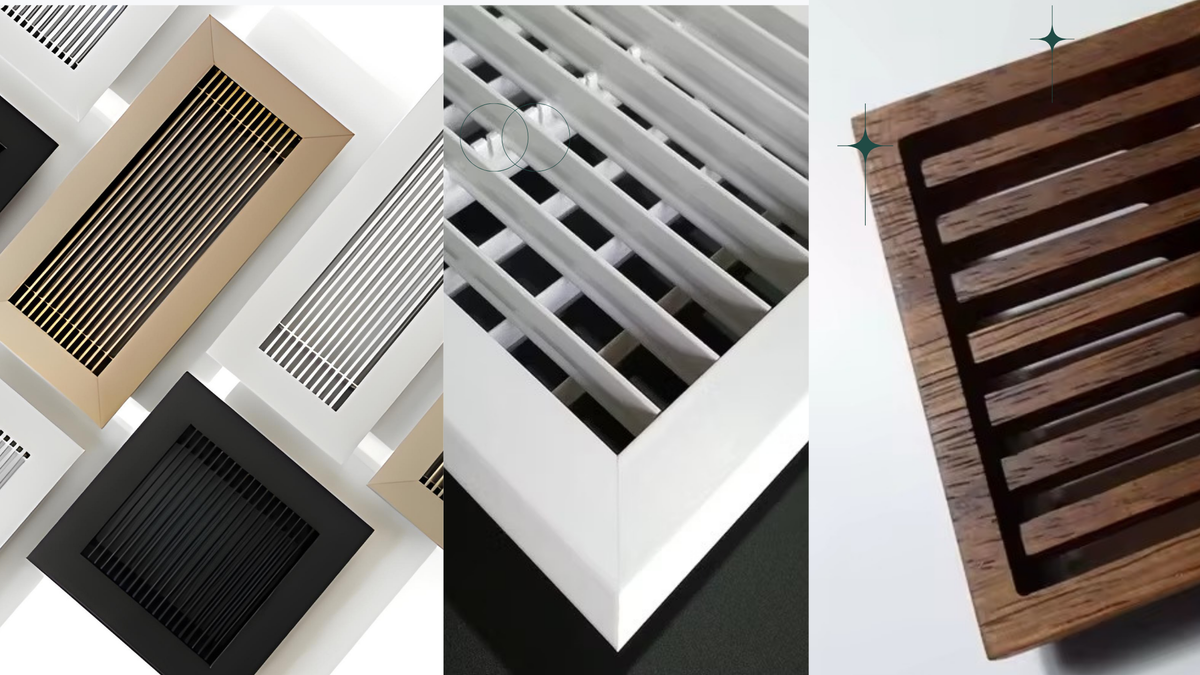

Common Materials for HVAC Grills

1. Steel

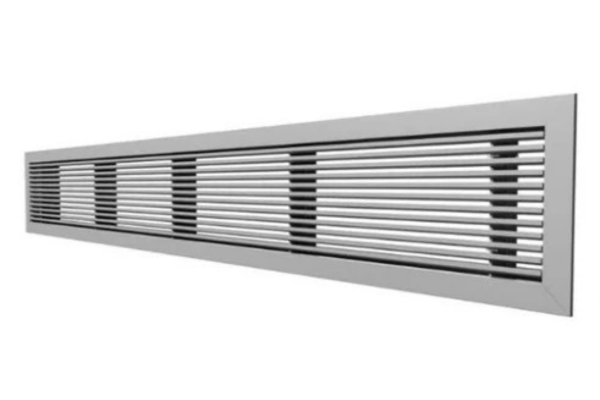

Steel is a popular choice for HVAC grills due to its strength and durability. It is economical and can withstand significant wear and tear, making it suitable for both residential and commercial applications. However, steel is prone to rust, especially in humid environments. Therefore, it is often recommended to use or to apply protective coatings to enhance its longevity in moisture-prone areas.

2. Aluminum

Aluminum grills are favored for their lightweight nature and resistance to corrosion. This makes them ideal for areas with high humidity, such as kitchens and bathrooms. Aluminum also offers a modern aesthetic and can be easily painted or finished to match interior designs. Although slightly more expensive than steel, the durability and low maintenance requirements make aluminum a worthwhile investment for many projects.

3. Plastic

Plastic grills, often made from materials like ABS or polypropylene, are increasingly popular due to their cost-effectiveness and ease of maintenance. They are resistant to corrosion and do not rust, making them suitable for all environments, including outdoor applications. Additionally, plastic grills are lightweight and safe for homes with children and pets due to their lack of sharp edges. However, they may not provide the same level of durability as metal options in high-traffic areas.

4. Wood

Wooden grills add a touch of elegance and can be customized to fit various interior styles. They are often used in high-end residential applications where aesthetics are a priority. However, wood requires careful maintenance to protect against moisture damage and scratches. It is generally more expensive than other materials, making it less suitable for budget-conscious projects.

5. Fiberglass

Fiberglass grills are known for their excellent insulation properties and sound-dampening qualities. They are particularly effective in commercial settings where noise reduction is essential. However, fiberglass can deteriorate over time and may pose health risks if fibers are released into the air, so proper installation and maintenance are critical.

6. Stainless Steel

For environments that require high durability and resistance to corrosion, stainless steel is an excellent choice. It is commonly used in industrial applications where grills are exposed to harsh conditions. While it is more expensive than other materials, its longevity and resistance to rust make it a reliable option for demanding environments.

Conclusion

When selecting materials for HVAC grills, contractors and consultants must consider factors such as the environment, aesthetic preferences, budget constraints, and maintenance requirements. Each material offers unique benefits that can enhance the overall performance of HVAC systems. By understanding these materials, HVAC professionals can make informed decisions that lead to better system efficiency and customer satisfaction.